0 to 60 in 5 Seconds – in Just 3 Weeks

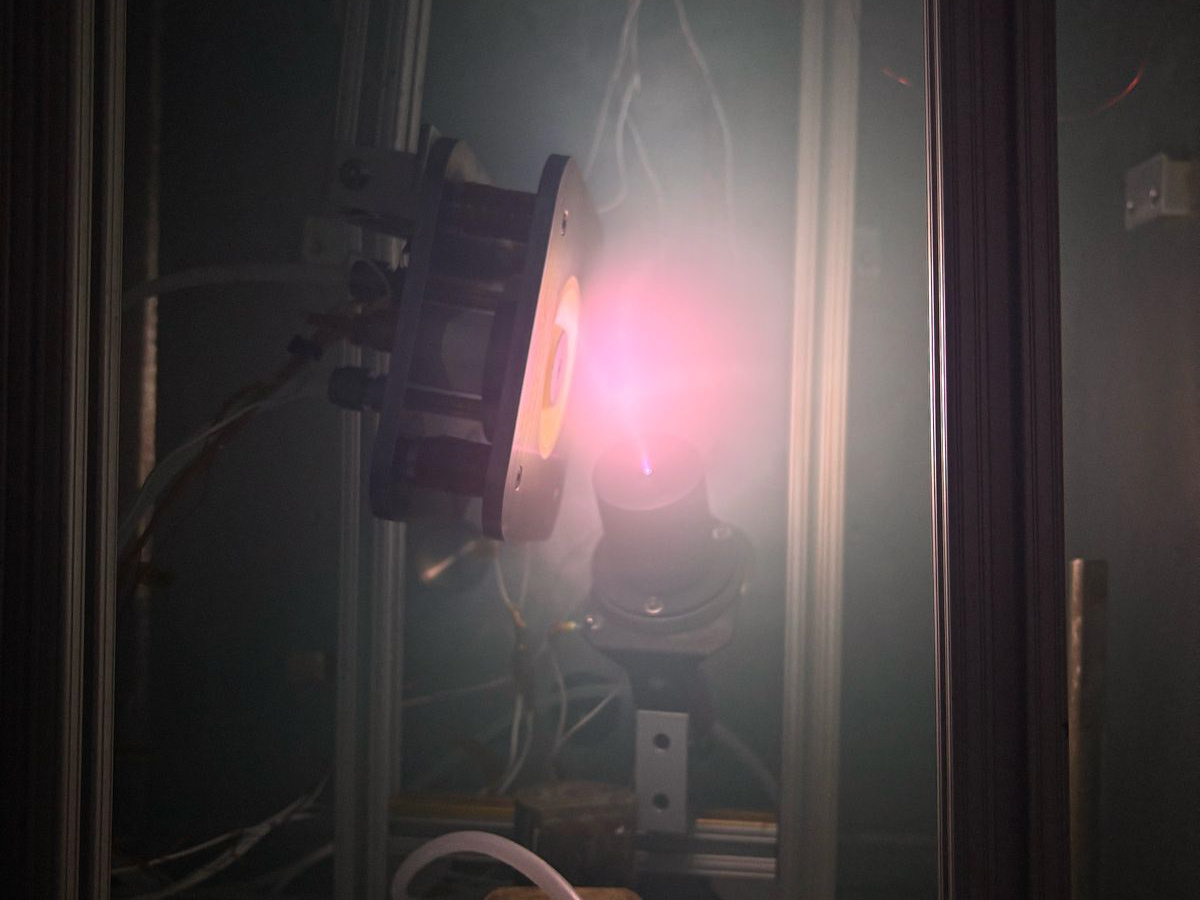

Project Vroom Vroom was an ambitious mission: design and build a fully functional electric Go-Kart from scratch that accelerates from 0 to 60 kph in just 5 seconds—all within 3 weeks. As a team of four, we engineered every system in-house.

As the sole Electrical and Computer Engineering student, I took on all electrical design and software development, from battery management and motor control to sensor integration and embedded programming.

From Scrap to Chassis

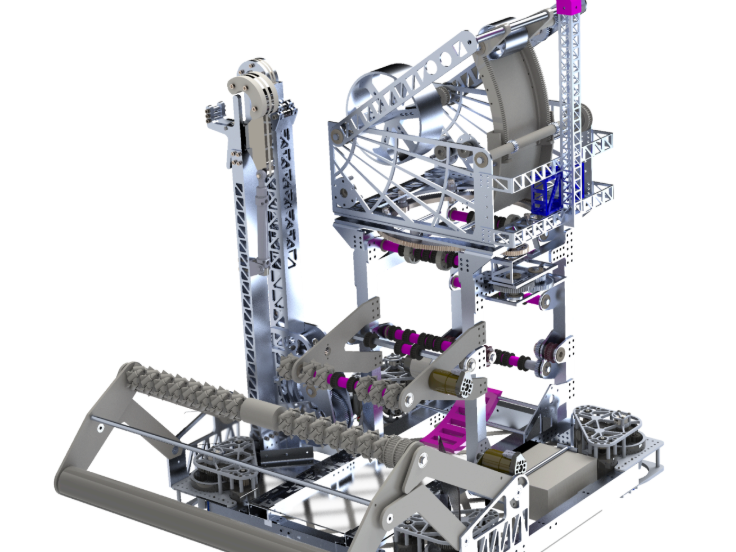

The project began not with shiny parts, but with rust. We dragged in a corroded, skeletal Go-Kart frame that had little more than a seat and half a body left intact. Most would have written it off as junk, but we saw potential. My teammates and I reinforced the frame, welded new mounts, and bolted down our first mechanical systems.

While they shaped the skeleton, I was already planning the nervous system: power, sensors, and control that would bring this machine to life.

Custom 48V Battery

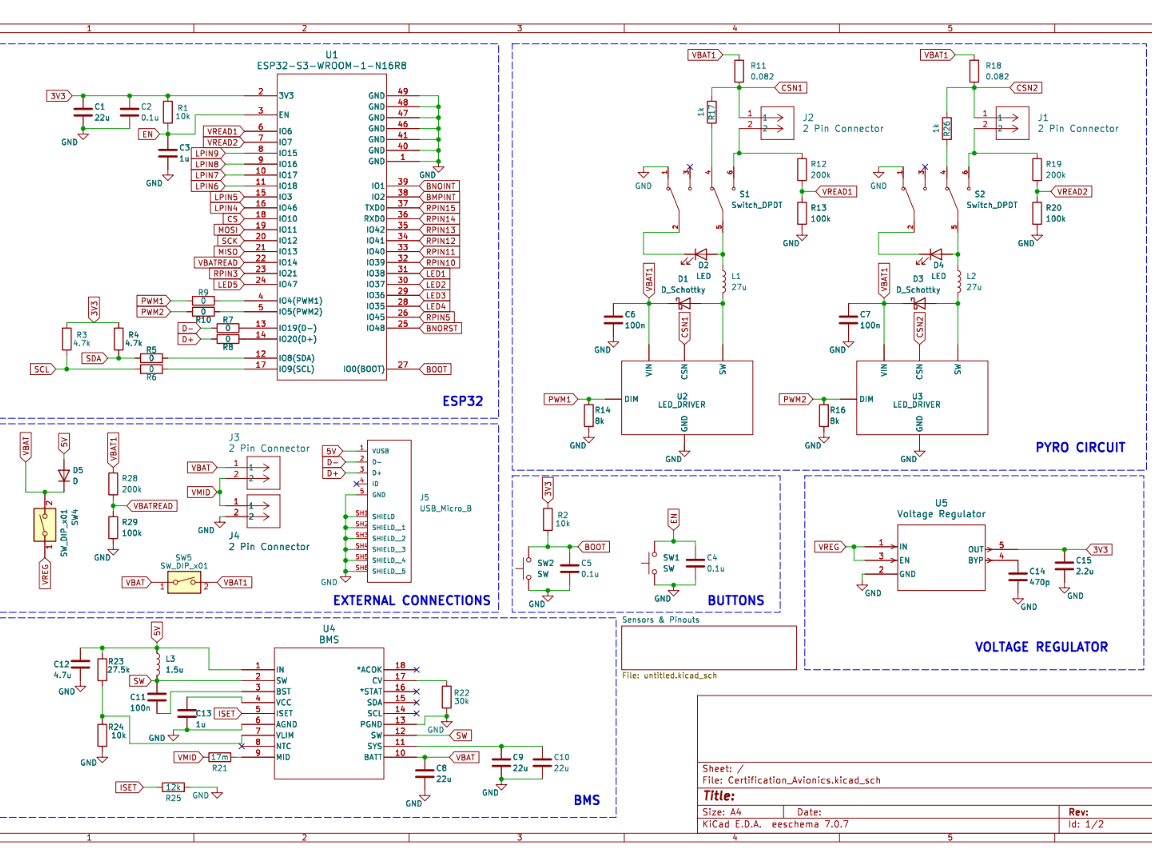

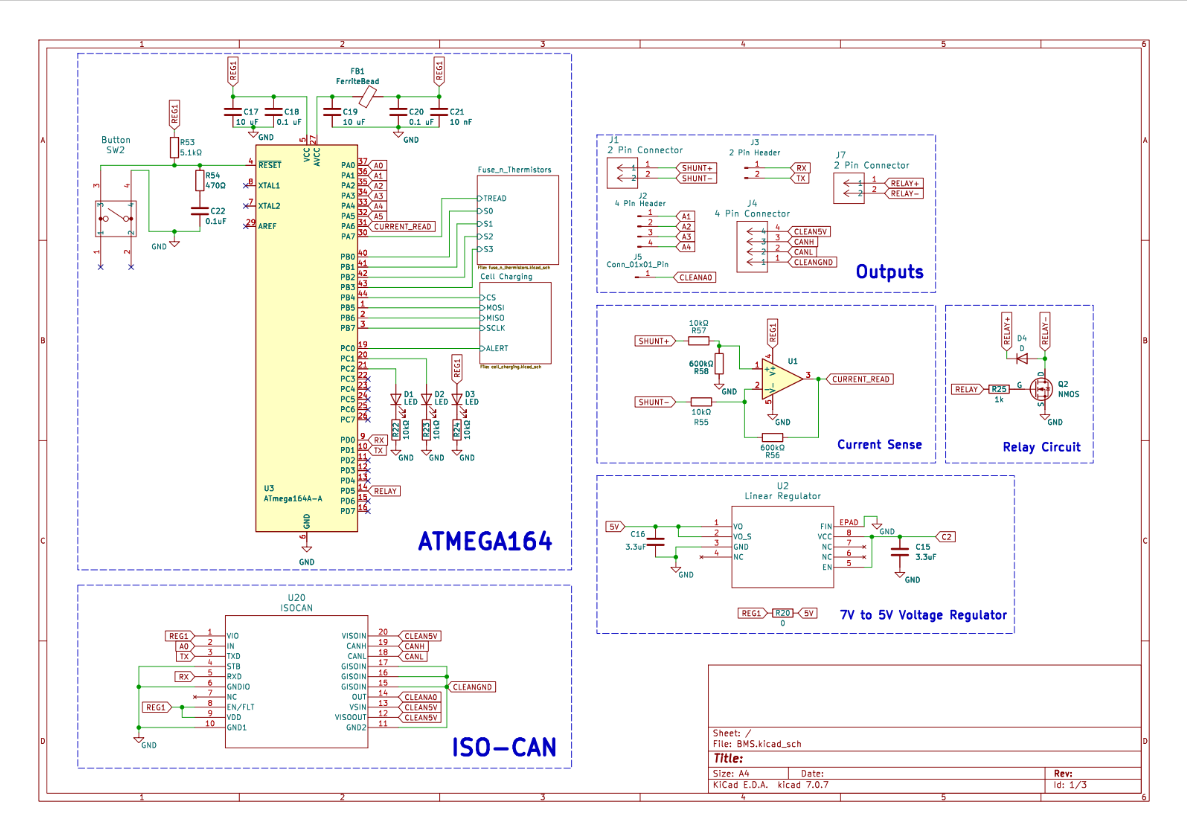

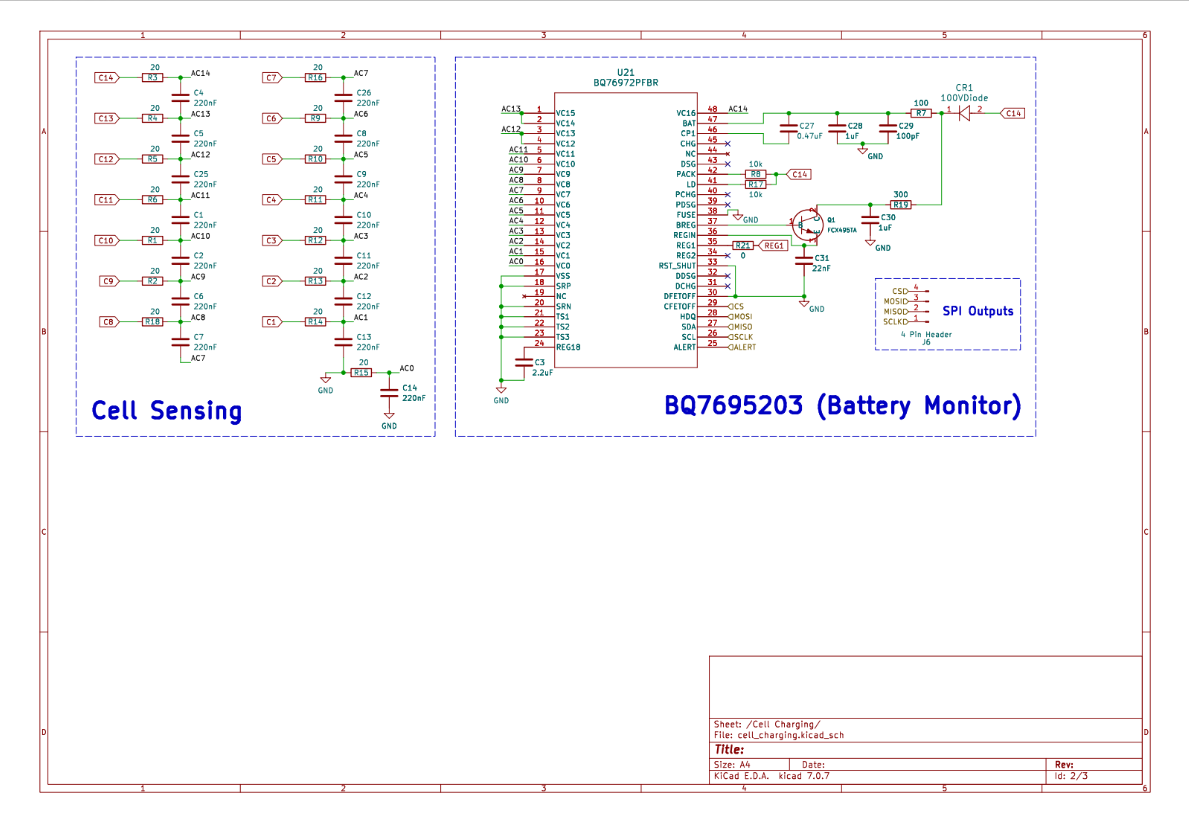

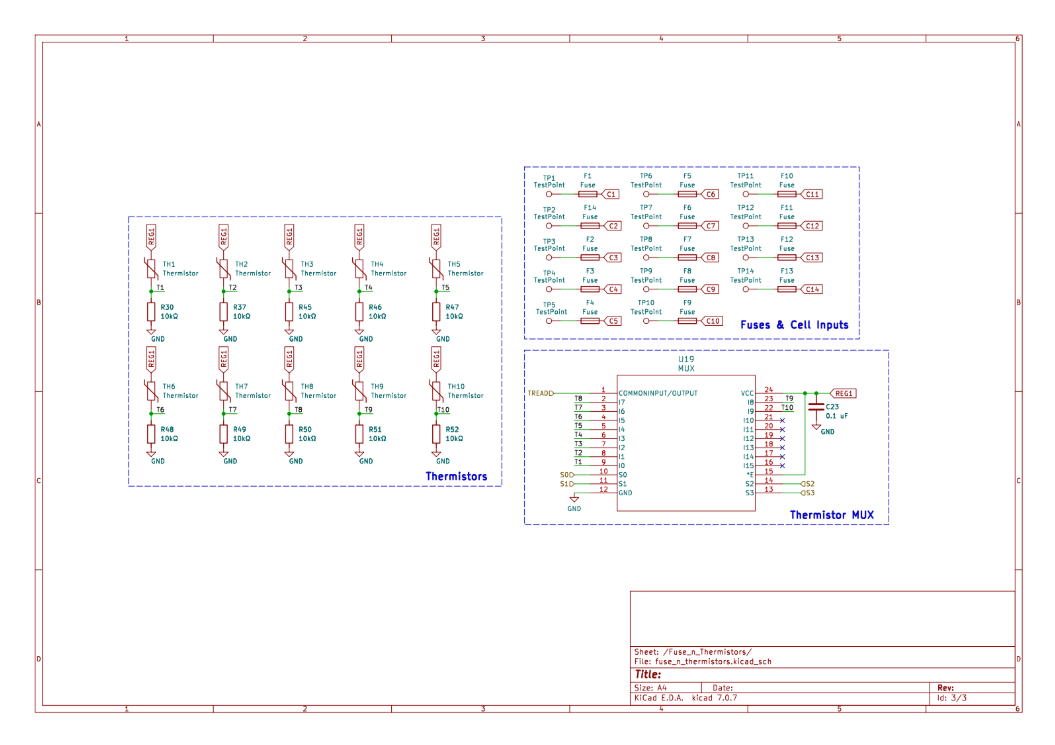

With no budget for commercial packs, I built our own power source. Cell by cell, I configured a custom 48V, 90A battery (13s2p), carefully balancing performance with safety. To protect it, I designed a custom Battery Management System (BMS) that monitored voltage, current, and temperature across the pack. I wrote embedded firmware for cell balancing, overcurrent protection, and thermal shutdown, ensuring the system could withstand brutal acceleration runs without risk.

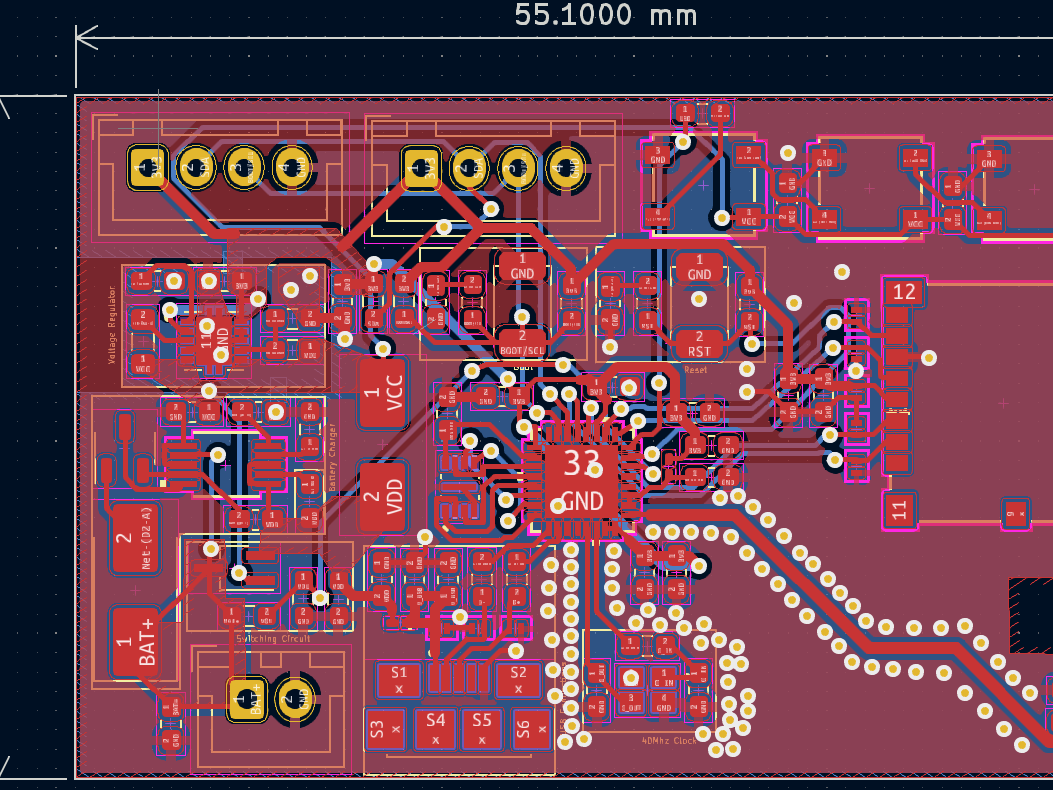

BMS Schematics:

BMS Board:

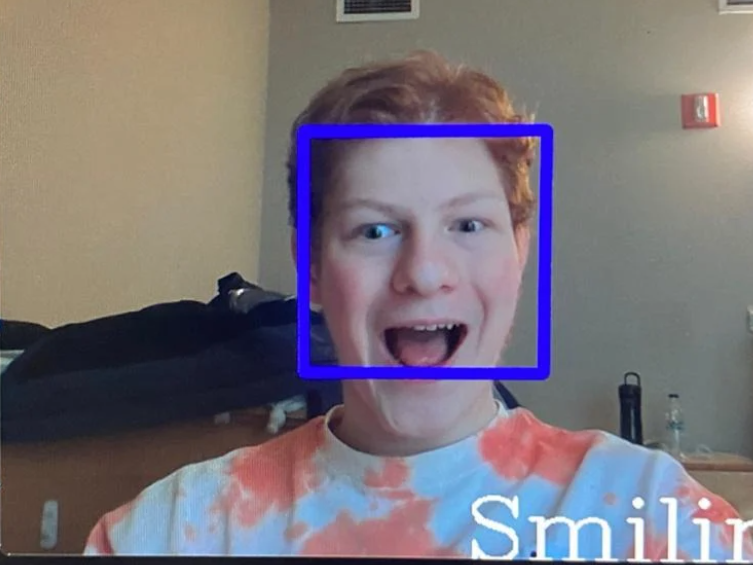

Sensors & Switches

To make the kart drivable, I wired and programmed four key inputs: throttle, brakes, emergency stop, and direction control. A linear potentiometer gave the throttle a tunable response curve. A limit switch fed brake signals into the motor controllers. The E-Stop instantly cut relay power in emergencies, while a keyed direction switch enabled forward, reverse, and neutral through Arduino inputs. Each sensor was wired into a single cohesive control network that fused mechanical reliability with electronic intelligence.

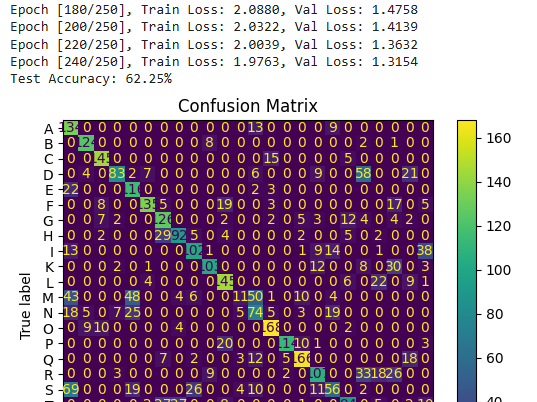

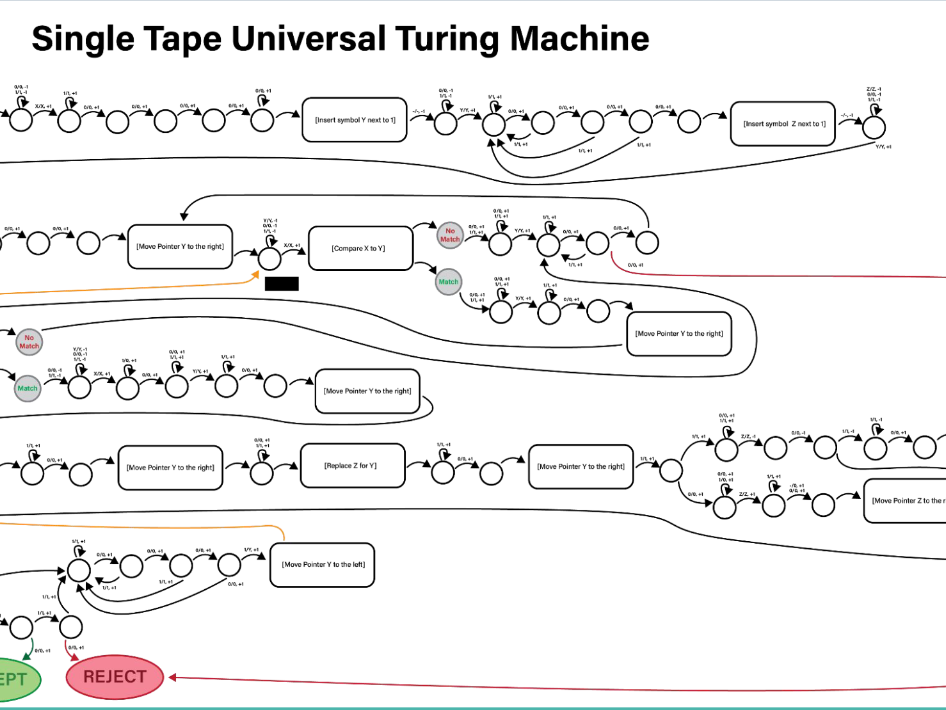

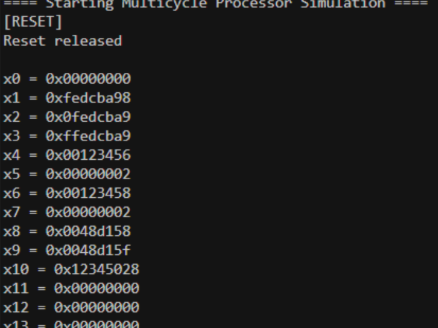

Embedded Systems & Control

The heart of the system was the code. I developed a PID controller to read wheel encoder data in real time and balance power between motors, giving us smooth acceleration and stability at high speeds. I layered on safety interlocks, WiFi telemetry, and tuning options that let us monitor speed, braking force, and thermal conditions from a laptop trackside. The BMS firmware was integrated into the same control loop—if a cell overheated or voltage sagged, the system cut power instantly, protecting both driver and hardware.

By the end of three weeks, the scrap frame we started with had transformed into a blistering, track-ready electric vehicle. What began as a pile of rust and wires had become a high-performance Go-Kart—proof of what can happen when mechanical grit meets electrical systems engineering.

Project Website: